English

English  Esperanto

Esperanto Afrikaans

Afrikaans Català

Català שפה עברית

שפה עברית Cymraeg

Cymraeg Galego

Galego Latviešu

Latviešu icelandic

icelandic ייִדיש

ייִדיש беларускі

беларускі Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ភាសាខ្មែរ

ភាសាខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Тоҷикӣ

Тоҷикӣ O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra Հայերեն

Հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba অসমীয়া

অসমীয়া ଓଡିଆ

ଓଡିଆ Español

Español Português

Português русский

русский Français

Français 日本語

日本語 Deutsch

Deutsch tiếng Việt

tiếng Việt Italiano

Italiano Nederlands

Nederlands ภาษาไทย

ภาษาไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা ভাষার

বাংলা ভাষার Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türkçe

Türkçe Gaeilge

Gaeilge العربية

العربية Indonesia

Indonesia Norsk

Norsk تمل

تمل český

český ελληνικά

ελληνικά український

український Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақша

Қазақша Euskal

Euskal Azərbaycan

Azərbaycan Slovenský jazyk

Slovenský jazyk Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Srpski језик

Srpski језик

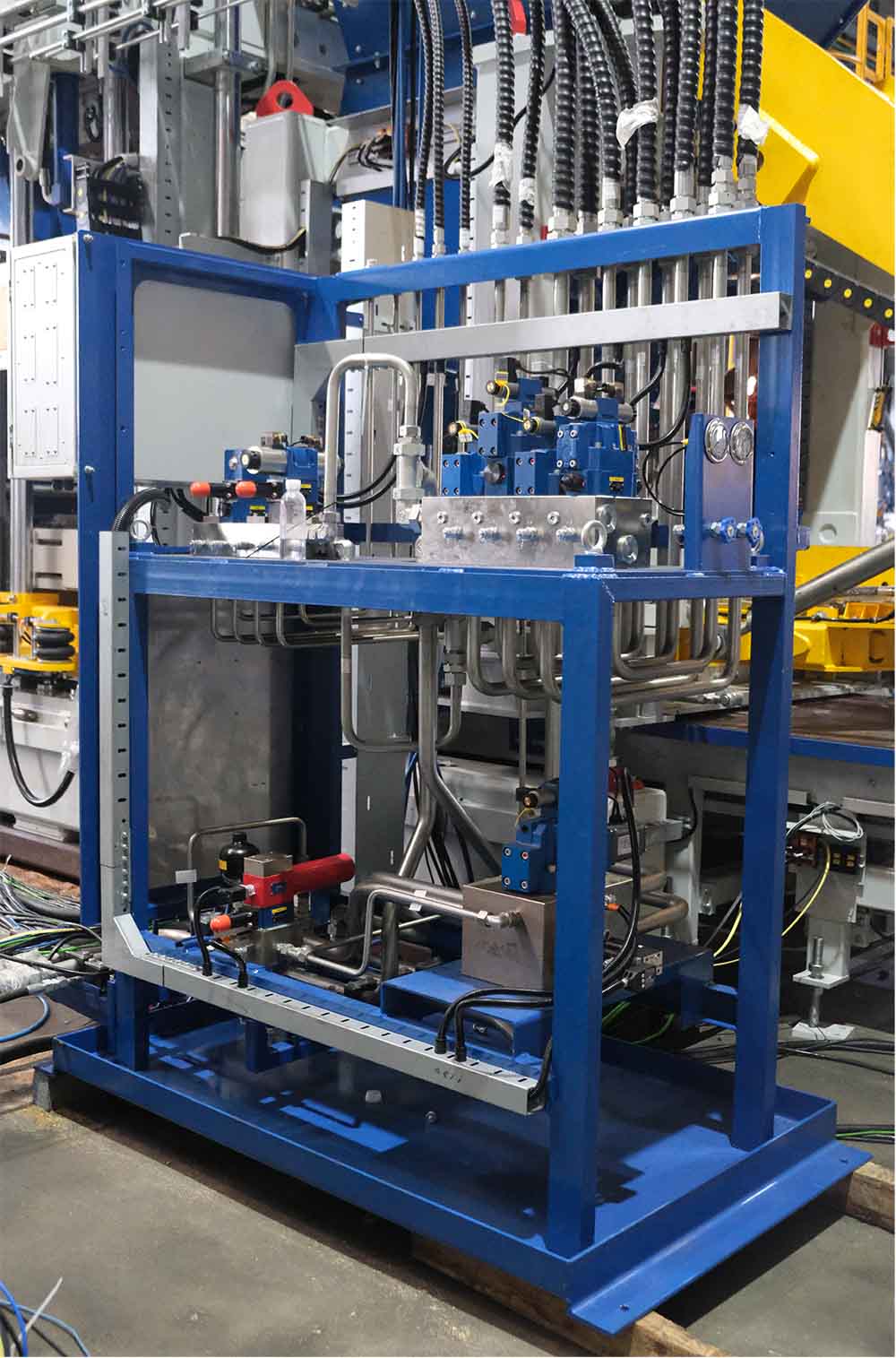

Napaka <0,1%! Kako QGM hidravlični sistem določa novo merilo za natančnost izdelave opeke?

2025-04-09

[Industry Challenges]

Traditional hydraulic systems have pain points such as large pressure fluctuations (±5%), high energy consumption (accounting for 35% of the total energy consumption of the Block Making Machine), and high temperature and easy leakage, which directly affect the quality of brick molding and production costs.

[QGM Solution]

1. Hardware architecture upgrade

Core components: Italian ATOS proportional valve + German HYDAC sensor + Swiss KAEFER sealing ring, with a pressure resistance of 35MPa;

Pipeline design: ALFAGOMMA three-layer steel wire braided hose is used, the explosion-proof pressure is increased by 3 times, and the service life is extended to 80,000 hours.

2. Intelligent control algorithm

Closed-loop feedback mechanism:

▪ Pressure control: Real-time monitoring of cylinder pressure, dynamic adjustment of proportional valve opening through PID algorithm, fluctuation range ±0.05MPa;

▪ Position synchronization: Double cylinder displacement error <0.1mm, ensuring uniform force on the mold.

Energy-saving mode: Automatically switch to low-pressure cycle in standby mode, reducing energy consumption by 60%.

3. Extreme environment adaptation

High temperature protection: The oil temperature cooling system can maintain the oil temperature ≤45℃ in a 50℃ environment to avoid pressure decay caused by viscosity drop;

Dust-proof design: The hydraulic station has an IP65 protection level, which effectively blocks dust from entering and is suitable for harsh working conditions such as around mines.

[Comparison of measured data]

| Indicators | Traditional system | QGM hydraulic system | Improved effect |

| Pressure control accuracy | ±5% | ±0.1% | 98% |

| Single brick hydraulic energy consumption | 1.2kW·h | 0.75kW·h | 37.5% |

| System failure rate (year) | 15 times | 2 times | 86.7% |

[Global application cases]

●Pakistan Karachi Expressway Project:

The QGong ZN1200 equipment is used to produce curbstones, and the average daily output is increased to 48,000 pieces, helping the project to be completed 3 months ahead of schedule;

●Kazakhstan Almaty Municipal Engineering:

Under an extremely cold environment of -30℃, it has been running continuously for 2000 hours without any faults, and the brick body qualification rate is 99.3%.

[Technology Evolution]

From the first generation of open-loop hydraulic system in 2015 to the third generation of intelligent servo system in 2024, QGM has solved the problem of "pressure pulsation under high-frequency vibration" through more than 200 pressure-flow coupling experiments, and the related technology has obtained 3 national invention patents.